USE:

To prevent planned intrusion by vehicles into high security areas, where deep excavations are not possible or not permitted.

SIZE:

Width of blocking segment 380mm

Width of casing 540mm

Length of casing 2500mm

Height of blocking segment when raised 985mm

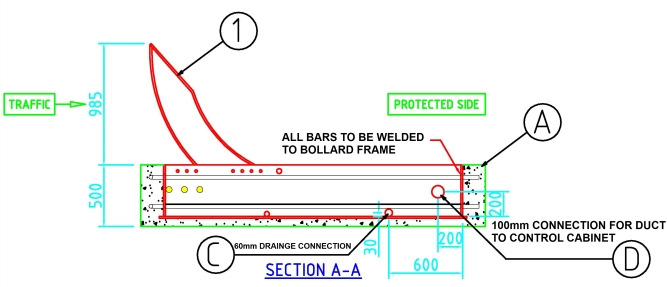

Depth into the ground 435mm

Control cabinet 1200mm high x 600mm deep x 900mm wide – variable with more than one raptor unit and special access control systems.

CONSTRUCTION:

The Raptor vehicle barrier generally manufactured from 15mm thick steel plate apart from the top plate of the blocking unit which is 10mm thick checquer plate fixed by button head set screws.

Cabinet from 3mm thick zinc plated and painted steel with integral lock

All manufactured in excess of BS6571 and welding BS4872.

DRIVE:

The blocking segment raised and lowered by hydraulic operation. The immersed pump , valve block and PLC controller housed in freestanding cabinet. This may be located up to 20m from the vehicle barrier.

Cabinet also to accommodate accumulator if required (see options).

Normal operating speeds 4.5 seconds to raise or lower. Fast operation via accumulator if fitted.

POWER SUPPLY:

415/220 three phase. 50Hz (all to suit country requirements)

PLC control voltage 110v AC. PLC logic voltage 240v DC.

Motor size 3KW.

CONTROL SYSTEM:

Latest version PLC controllers with in-built safety features and manual release. Facility to link all access and automated systems, fire alarms, and other devices.

OPTIONAL VISUAL AND ELECTRONIC SAFETY EQUIPMENT:

- Stop/no entry signs fixed to freestanding post or to drive unit cabinet

- Traffic lights, red/green, 200mm diameter in black casing installed above drive cabinet or on freestanding posts – single or double sided.

- Flashing yellow signal light

- Below ground vehicle detection loops essential for automated systems.

- Electronic eye beams.

- Cold weather protection with space heater in cabinet and heating coil fitted to hydraulic hoses set into duct and temperature control around the ram.

NB: There are no entrapment areas on this unique product

OPTIONAL CONTROL FUNCTIONS:

- Single direction entry or exit

- Dual direction entry and exit

- Push button up-stop-down to be sited in guard house

- Key selector switch – automatic function/manual/remote

- Intercom and pedestal

- Card readers

- Tickets and cash (not in our remit)

FINISH:

All units hot dipped galvanised to British standard EN ISO 1461 then roadblocker primed and painted black and yellow, drive cabinet primed and painted grey. Other RAL colours available.

INSTALLATION:

No pre casting of foundations are required for the Raptor Vehicle Barrier. Normal excavation with hose, power cables, and drainage ducts. Backfilled with maximum of 2cubic metres of C35 concrete – vibrated together with 27m overall length of reinforcing bar, threaded through predrilled plates on raptor housing.

TESTING AND CERTIFICATION:

The raptor has been physically tested and certificated under the

PAS 68 requirements giving result of:

V/7500(N3)/90/90:3.3/18.9

Click to impact testing

|